When it comes to low prices and high quality, China mould supplier and injection molding companies are hard-to-beat. Many foreign customers understand the advantage of sourcing injection molds and plastic molding parts directly from China companies, They also understand that the development of a new product, injection molding process has more benefits than stamping and vacuum thermoforming.

Any mould or plastic parts you purchase can obtain a satisfactory price in China, but don’t just care about the price and ignore the other more important, even spent 1 dollar. Do not want to buy garbage back, as a beginner you don’t know who are you looking for suppliers, start slowly, spend time learning to explore. You will first focus on several key steps in the process.

Finding a china mold company

Use Google, it offers you a simple, straight-forward channel for locating overseas suppliers, but not all online directories are created equal. But not all the companies you find are what you really need. Cnmoulding advice, through customer understanding and presentation. To ensure that they are legitimate companies and be able to provide the mould and products they claim.GOOGLE is trustworthy in this respect. Some commercial sites. Because of the money collected to determine the company’s ranking, allowing vendors to post their own content without any verification.

The second option is to go directly to the plastic mold factory you have chosen to investigate whether they are a real plant, not a prop. Although the cost of such travel requires more effort and higher than the Internet connection, it also provides an opportunity and your injection molding suppliers face to face, to understand the mould company design & manufacturing capacity, their characteristics and strengths, often visit, at the same time enhance each other’s feelings.

Selecting and Working with an injection molding company

You can start a small project to test the water, which is responsible for both sides. In order to get the manufacturer’s attention, you must show past purchasing records. And show the potential as a long-term business partner. Introduce your company and project, and then ask for a similar material sample and plastic molding sample.

As a professional buyer, you must not only look at the sample. It is more important to check the design drawings and the real injection molds in the factory, to ensure that you see not just a sample. Which can be bought from any market. “Select your plastic injection molding supplier have 6 reasons” is very helpful for the procurement of the article, we can refer to.

What else should you look for when considering a mould manufacturer in china?

For plastic injection molding products or plastic products. You also need to tell the manufacturer, you need the quality, packaging requirements, gate location, painting position, and so on. Also remember that for the materials you choose, you are legally responsible for ensuring that all products meet the environmental requirements of your country. Find out if your potential supplier has exported molds or injection molding products to the United States, Europe. If so, what kind of export industry, the number of precision, appearance, this will become the basis for your choice. If these companies can provide materials, quality certification is more secure.

Know what you need to design a new product certification, and then tell your potential production plant! Do not buy any plastic products that can not provide proof of material from suppliers, will bring you a lot of trouble. Once you have chosen your Chinese mold manufacturer to deliver your order. It is particularly important to inform the engineer and the mold maker of all the details of the product design, assembly, inspection, etc. The good cooperation between the two sides is directly related to the quality of plastic products, delivery time, and the first T1.

Paying Method

The most common payment terms are 50% advanced, 50% after sample confirm before shipping, Some customer like the way is 30-40-30, although it’s less common. Under 30-40-30 terms, the buyer puts 30% down and pays 40% at shipping and the final 30% upon receipt and inspection. But a lot of good mold suppliers don’t accept such payment methods, it is important you should remember, mold company is your assistant.

Quality Control

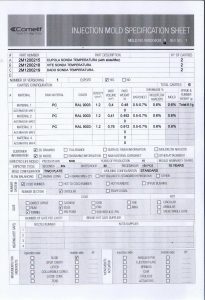

If you buy injection molds, you check the mold quality in two ways: trust the supplier, small batch production inspection. In a small order, you can choose to trust the vendor. It should be noted that prior to mold manufacturing, mold design drawings must be confirmed, including the gate position, ejector pin Location Flow Chart, mold size, cooling design, the standard joints, hot runner Location Flow Chart design,

If you buy a large mold, you can choose to produce 1000-3000 set products in an injection molds company. So that the mold to the best state and then exported. If you purchase plastic injection products, you can consider hiring an employee to help you check the product in China. Do not consider hiring a third-party inspection company, good cooperation will destroy by rigorous inspection methods between customers and suppliers.

Shipping and Logistics

For samples and small batches, high-value products, and the express couriers may make sense – because hungry they need quick service. Airfreight is proving to be the most effective option for shipping relatively small orders or important goods. Large quantities of goods shipped by sea ships can take up to 15 days or more. (not including clearance time) but the air transport cost is savings (especially larger orders) can be substantial. Our article is base on our previous customer experience, can replace the lesson, save your cost.